Pertinent Measurements Related to RNG Processing

Pertinent Measurements Related to Renewable Natural Gas Processing

By Narge J. Sparages, Panametrics, a Baker Hughes business

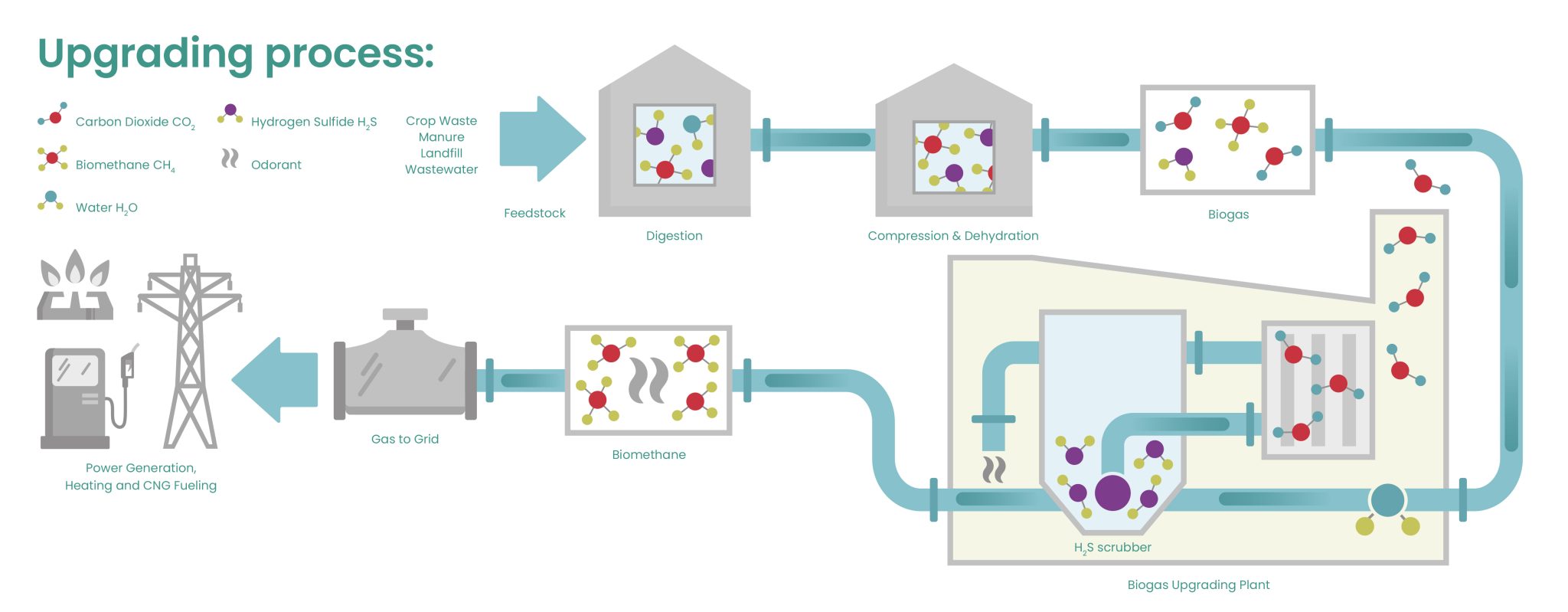

Renewable natural gas starts from raw biogas that comes from a variety of sources. It is cleaned, separated, and upgraded into a pipeline-quality fuel. The resultant carbon dioxide goes through similar steps for use or sequestration.

Measurement solutions support biogas collection. Two examples include monitoring oxygen content in an anaerobic digester or in landfill gas. Below are examples of where analyzers are used in the upgrading process.

Along the value chain, the analyzers required fall into two categories: safety and quality. Let’s explore how Panametrics analyzers bring value to these processes.

Raw biogas is saturated with water. Chilling knocks out bulk moisture. Capacitive polymer moisture transmitters like the MMR31 indicate the efficiency of this dehydration, preventing damage to downstream analyzers.

Membrane filters separate the carbon dioxide and methane. Most measure the amount of carbon dioxide and methane going in, and then the purity of the methane and carbon dioxide on either side of the separation.

Carbon dioxide and methane in the inlet and two outlets behave as binary gas mixtures. A binary gas analyzer that takes advantage of the thermal conductivity differences of these two gases provides a percent-level analysis of carbon dioxide in methane. With no moving parts, this methodology requires little maintenance. The XMTCpro is well-suited for this analysis.

Measurement panels include these binary gas analyzers and an XMO2pro oxygen analyzer that ensures the inlet gas is below the lower explosive limit. This thermoparamagnetic oxygen analyzer has no moving parts, thus making it ideal for this application.

For lift into the natural gas grid, the moisture and oxygen levels must comply with local tariff limits. Further dehydration prepares the gas for commercial use.

The pro.IQ aluminum oxide sensor system or the Aurora tunable diode laser analyzer reliably monitors the dehydration process. Portable versions are available for spot checks. The O2.IQ employs galvanic fuel cell technology for trace oxygen measurements.

Carbon dioxide is dehydrated for local sequestration, pipeline transportation, or to prepare for food and beverage use. The moisture and oxygen technologies employed for pipeline natural gas also apply.

Biogas upgrading skids are manufactured and maintained by skilled artisans and experts in the collection and cleanup of biogas. They rely on the expertise of analyzer manufacturers to provide an integrated solution that prepares the sample gas for the required analysis.

For more information, read our Canadian Biogas Magazine.

Comments