Pumping, Grinding, & Conveying Equipment for Biogas Applications

By NETZSCH

Biogas plants require a multitude of complex fluid pumping and grinding solutions which demand solids handling capabilities for high-viscosity medias that can offer low-pulsation conveyance as well as assist in reducing lifecycle costs.

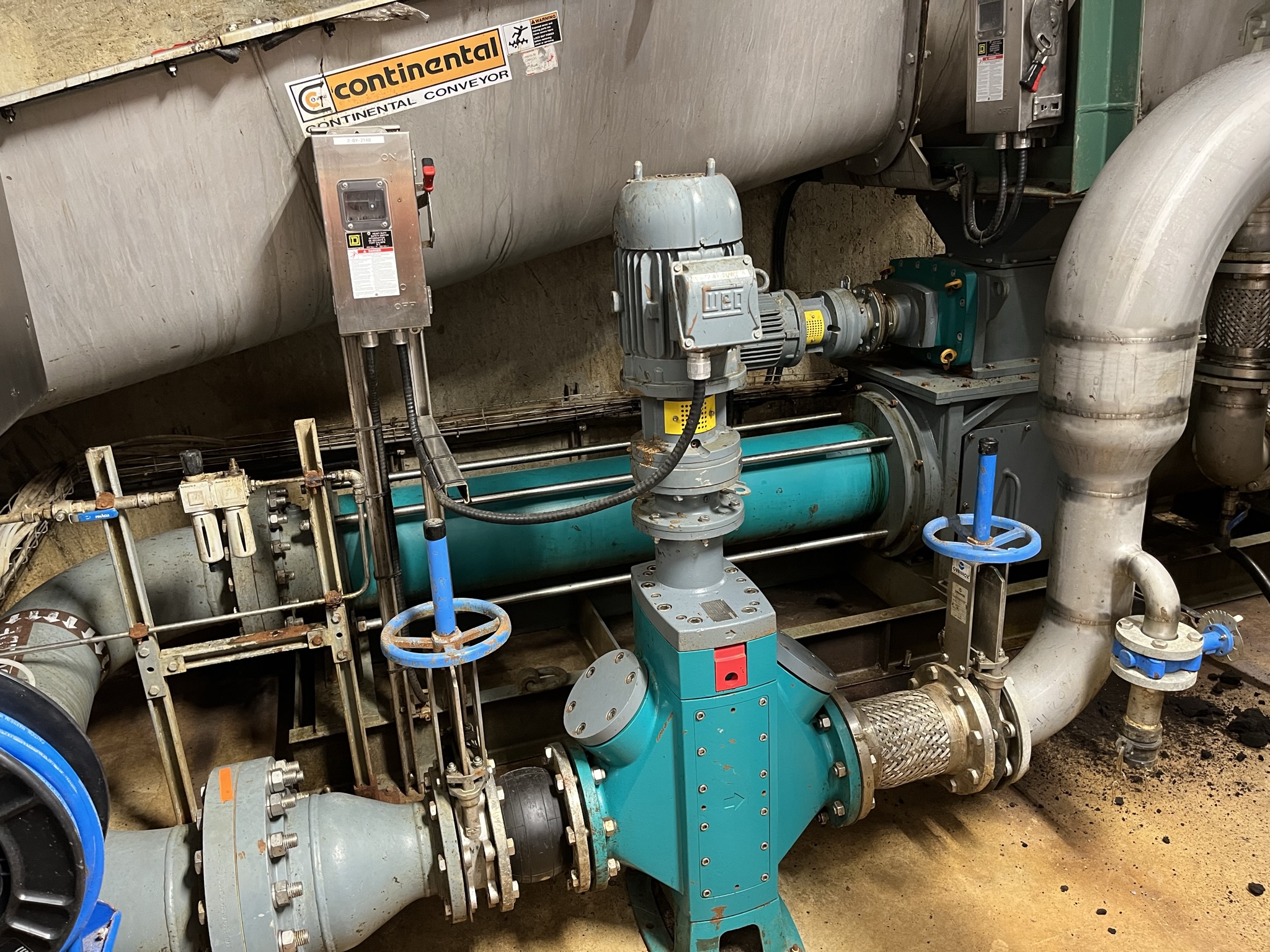

Lobe Pumps

Designed to produce high flow at low to medium pressures, lobe pumps offer compact footprints. Their versatility allows them to be installed in just about any orientation.

Capable of handling a wide range of viscosities, solids, temperatures, abrasion, and corrosive/acidic process fluids, the lobe pump boasts a robust design which contributes to its longevity and operational flexibility in the field.

The majority can have dry-run capabilities and handle upset process conditions with ease. Standard designs can deliver up to 4400gpm and 116psi – depending on the manufacturer.

Mixing Pumps (Progressing Cavity)

Saving space and minimizing a plant’s overall footprint means money saved.

Researching the types of equipment available on the market that can mix and convey ground bio waste, food waste, liquid manure, slaughterhouse waste, co-substrates, concentrated substrates or slop would likely lead to your stumbling upon the progressing cavity pump.

The pumps best suited for these applications will be equipped with a hopper, a conveying screw, and a housing design capable of maximizing the amount of product being fed into the conveying elements (rotor/stator).

Other advantages gained when employing this type of pumping technology include increased gas production, a continuous low-pulsation conveyance that is independent of pressure and viscosity, as well as high-pressure capability, robust drive seals, and low investment and operating costs with high operating safety.

Grinding Systems

Several grinding technologies exist and can be applied in biogas applications. The most popular are the universal cutting-plate macerator and the twin shaft grinder.

This equipment protects solids not meant to enter a pump and are primarily installed upstream of any pumping technologies, and particularly at product receiving areas at any given biogas facility using trucked-in materials in their process.

Much like the attention that needs to be paid when selecting a pump, the same careful attention is necessary when applying these grinding systems. Without them, there’s a high risk of pump damage or clogging.

About NETZSCH Canada, Inc.

NETZSCH Canada, Inc. represents NETZSCH Pumps & Systems in Canada, a global provider of fluid handling solutions for over 60 years. Specializing in complex applications across industries, the company offers a range of pumps, including NEMO® progressing cavity pumps, TORNADO® rotary lobe pumps, NOTOS® screw pumps, and PERIPRO® peristaltic pumps, along with grinders, macerators, barrel emptying units, and metering technology.

For more information, read our Canadian Biogas Magazine.

Comments