Digester Startup and Commissioning

By Azura Associates

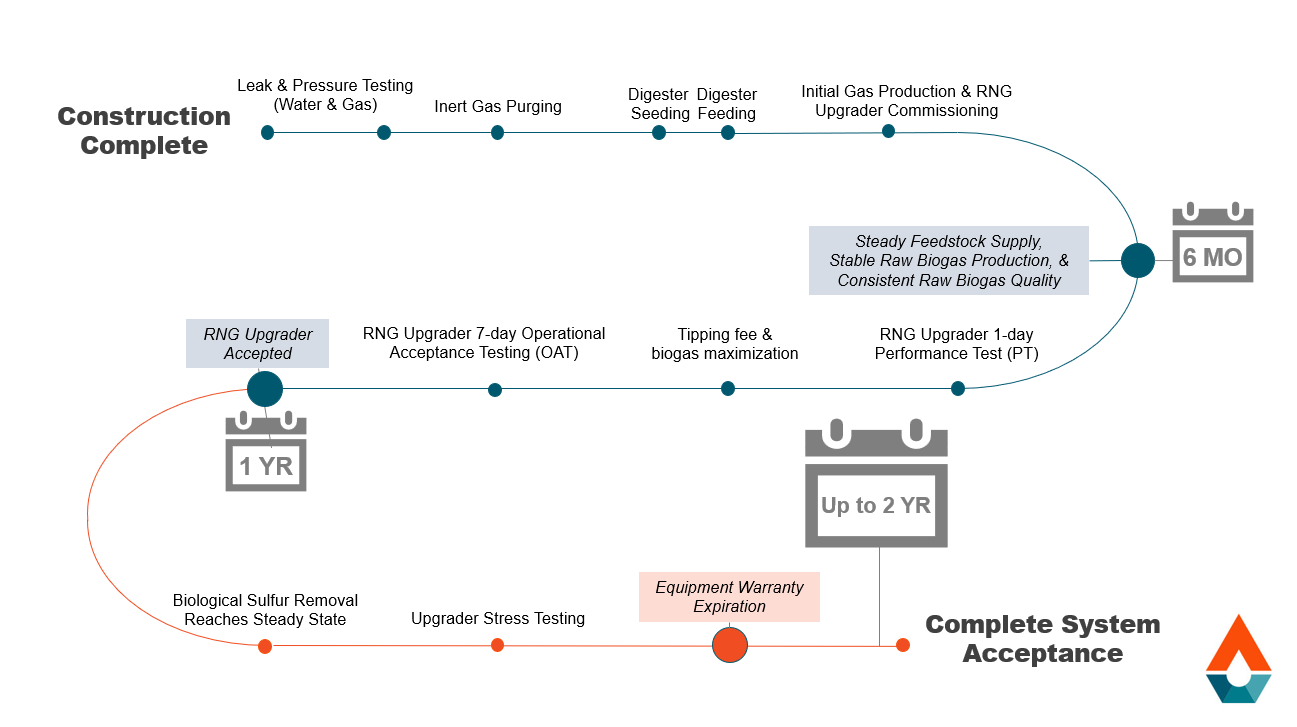

Digester biology is most sensitive and fragile during startup and commissioning (S&C). It is imperative that owners and developers ask tough questions of all project stakeholders to effectively quantify, assign, and manage risk during this period. There are 5 key considerations that are often overlooked during S&C of anaerobic digesters.

Pressure and Leaks Tests

Every digester project, whether you have a lagoon or a tank system, will need to undergo wet and dry testing. If any leaks are detected, there could be months added to the project schedule.

Inert Gas Purging

Best practices recommend purging the feed, gas, and recirculation lines; not just the digester headspace.

Seeding & Feeding Ram-Up

You can think of digester seed like the kindling for your fire, it is essential to get your digester biology active and generating biogas quickly. Securing a sufficient quality and quantity of seed can accelerate your startup as the biology acclimatizes to the digester feed. Trucking large volumes of seed can be expensive, so striking the right balance between cost and speed is critical.

Your ability to start feeding your digester and begin generating biogas is highly dependent on your seeding schedule. Beyond ensuring good seed quality and quantity, pre-heating of your seed material and carefully managing digester pH can help keep your schedule on track.

Performance Warranty / Guarantees

All the equipment at your digester plant will come with a warranty period. Most performance warranties do not consider the time required for biological startup, meaning you may not have time to stress test your equipment before your warranty period expires.

Make sure to discuss these contractual terms and any potential scheduling challenges with your EPC and technology provider so that you’re aware of the risk you, as an owner, will inherit in the event these risks occur.

Acceptance Testing

Once initial gas production has started and your biology nears a ready state, only then can you properly stress test your gas upgrader and see how it reacts with the biogas being produced. By the time stress testing is completed, you could be passed two years from the point when the construction of your project was substantially complete.

It’s critical to negotiate acceptance testing criteria with your technology provider and make sure you’re aware of potential schedule implications.

Conclusion

Starting up any bioprocess system is a complex task that requires careful planning, monitoring, and adjustment to ensure successful and sustainable operation.

But it does not have to be overwhelming.

Just as every farmer knows how to seed and grow a crop, bioprocess engineers are well-equipped to oversee biological startup and commissioning.

For more information, read our Biogas Efficiency Magazine.

Comments