The Anaergia Advantage at Rhode Island Bioenergy Facility

Transforming Waste into Energy: The Anaergia Advantage at Rhode Island Bioenergy Facility

BiogasWorld’s Alexandre Lapierre enjoyed visiting the Rhode Island Bioenergy Facility (RIBF) this summer and learning about Anaergia’s advantage.

Anaergia Integrated Systems for RIBF Transition to RNG

Rhode Island Bioenergy Facility treats nearly 100,000 tons of organic feedstock annually, diverting organic waste from landfills and producing 320,000 MMBTU of renewable natural gas. Initially, the facility was equipped with a combined heat and power unit and produced renewable electricity, but it was further decided that biogas should be used to produce renewable natural gas (RNG). Anaergia’s engineers delivered the solution, which included an upgraded biogas conditioning system, a CO2 removal unit, a product compressor, and a grid entry unit. As the unit was delivered fully integrated, the installation and commissioning were efficient and fast.

Kevin Bell, Facility Manager, RIBF, confirms, “We have been impressed with the process from procurement to installation and now into operation. We are a satisfied customer and those that know, trust Anaergia.”

Anaergia BUG System and its Operation

According to Thomas Jakositz, RNG operator, the Anaergia BUG is built with the operator in mind. “The automation and controls are rock-solid, which means we don’t have to worry about unexpected issues. The interlocks and alarms are super user-friendly, so it’s easy for us to keep everything running smoothly,” confirms Thomas. “The controls are seamless, ensuring that production runs without a hitch.”

Additionally, Anaergia provides the support the operators need. They are in the same time zone, so the solution is just a quick call away, meaning less downtime and more reliable operations.

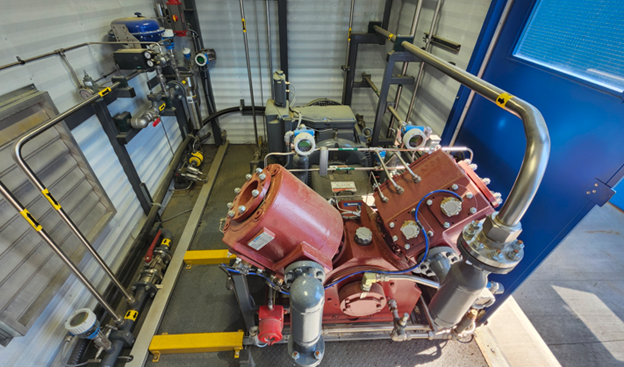

Biogas Compressor is an Important Component in the Biogas Upgrading System

The RIBF project uses an ACS two-stage biogas screw compressor which saves approximately 568,000 kW/year of electricity and reduces CO2 emissions by 488,000 pounds compared to a single-stage compressor. Additionally, ACS installed a heat recovery system on the biogas compressor and equipped both compressors with Variable Frequency Drives to adjust motor speed based on gas flow fluctuations, resulting in further energy savings on site.

Compressors are manufactured in North America, so using locally sourced components supports sustainable practices by reducing the carbon footprint and packaging waste. Plus, it also ensures the equipment meets North American codes and standards.

Jean-Francois Ouellet, Technical Sales with ACS, confirms, “ACS partnered with Anaergia to deliver a top-performing biogas upgrading package that is unmatched. What sets our biogas compressor apart is our focus on energy savings and efficiency optimization.”

Anaergia’s Advantage

According to Sasha Scattergood, Vice President, Technology, Anaergia, the operators and customers of Anaergia want “a biogas upgrading system that is simple and reliable.”

The drawbacks of most existing upgrading units are the use of outdated control systems, European design and the fact that they do not clean their gas well enough which leads to clogging of the expensive gas membranes. As a solution, Anaergia’s Biogas Upgrading system is operator-focused, is designed and built in North America, and makes the biogas extremely clean.

Sasha Scattergood affirms that Rhode Island Bioenergy Facility “is just the start, and we look forward to delivering more amazing biogas upgrading plants to North America, it’s clear that those who know, trust Anaergia.”

Watch the video of BiogasWorld’s visit to the Rhode Island Bioenergy Facility:

To learn more about Anaergia, please visit https://www.anaergia.com or send an email to info@anaergia.com.

Comments