Precision Monitoring: Elevating Biogas Efficiency with MRU Instruments’ OPTIMAX and SWG100 Analyzers

By MRU Instruments

In the rapidly expanding biogas sector, where renewable energy from organic waste promises sustainability and cost savings, maintaining peak efficiency is paramount.

Fluctuating gas compositions, corrosive contaminants like hydrogen sulfide (H₂S), and strict regulations can erode yields and raise risks. Enter MRU Instruments’ OPTIMAX and SWG100 Biogas Analyzers—cutting-edge tools designed to deliver real-time insights, allowing operators to fine-tune processes, minimize downtime, and maximize energy output.

The OPTIMAX Portable Biogas Analyzer is a compact, 1.7-pound handheld device built for field technicians working across digesters, landfills, and biomethane plants.

Its 15-hour Li-Ion battery supports long on-site assessments, while dual NDIR sensors provide precise methane (CH₄) and carbon dioxide (CO₂) readings (0–100% range, ±0.3% accuracy).

Electrochemical sensors measure oxygen (O₂, 0–25%), H₂S (up to 10,000 ppm overload), and hydrogen (H₂, up to 2,000 ppm). An integrated condensate separator with a water-stop filter and internal flow monitoring protects against moisture contamination for reliable readings in demanding conditions.

Designed for proactive efficiency management, the OPTIMAX detects imbalances—like high H₂S levels that corrode engines or low CH₄ concentrations signaling feedstock issues, allowing immediate process adjustments to boost calorific value (calculated up to 36 MJ/m³) and optimize CHP systems.

With NESHAP-compliant CO monitoring for landfill gas wells, and the ability to store 32,000 measurements via Bluetooth and WLAN connectivity, it enables seamless integration with digital workflows.

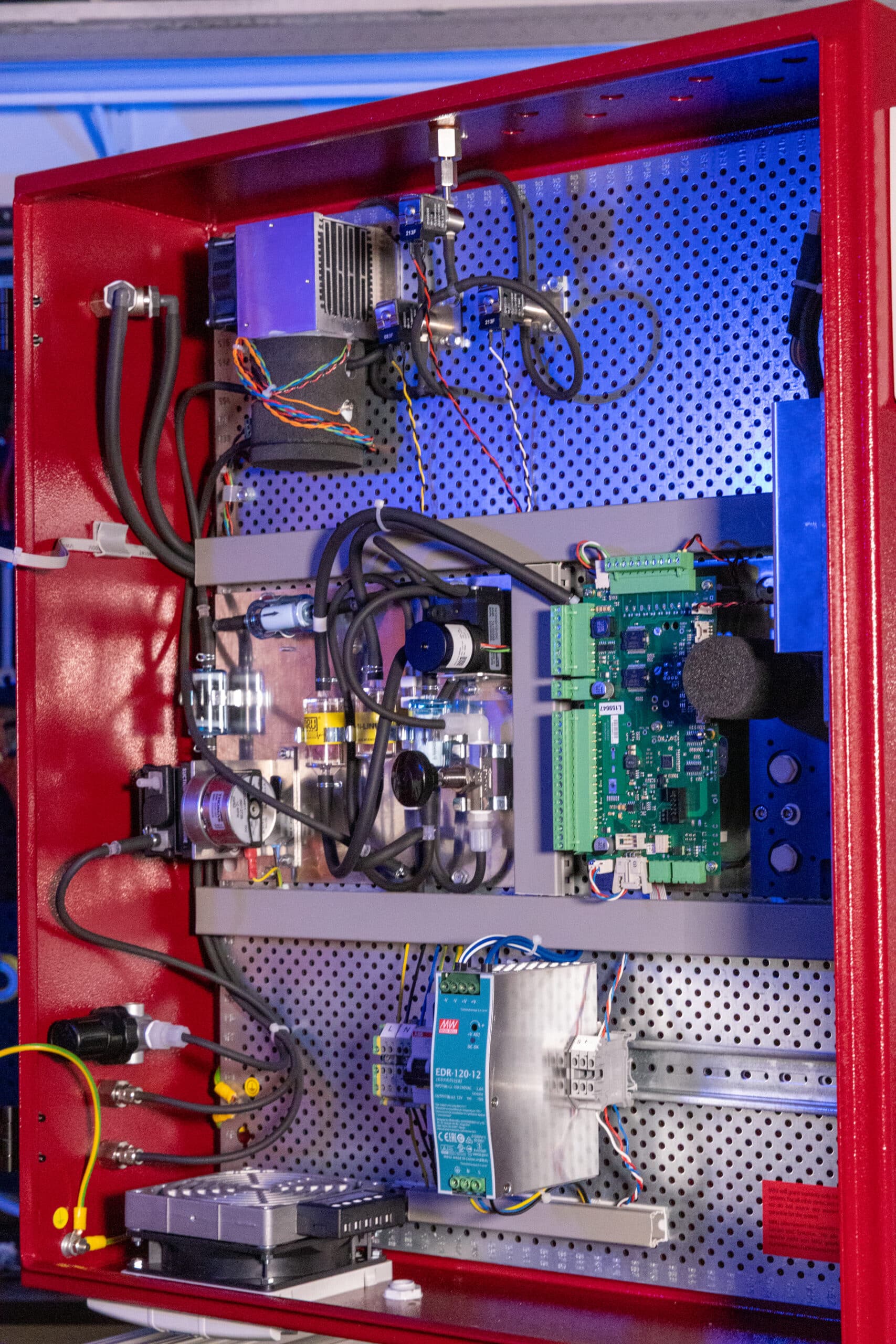

For continuous oversite, the SWG100 Biogas Analyzer provides 24/7 monitoring in fixed installations.

Housed in a rugged IP54 aluminum cabinet, it performs reliably in harsh environments such as dairy digesters or coal bed methane sites, managing inlet pressures from –100 to +250 mbar without dilution (except in high-H2S landfill configs).

It measures CH₄, CO₂, O₂, H₂S, H₂, and CO with comparable precision, adding discontinuous sampling for trace gases and auto-calibration with ambient air or user-supplied mixtures.

The SWG100s’ efficiency edge lies in its multi-site capability, monitoring up to 10 sites via time-sharing, featuring pressure /temperature compensation and event logging.

Safety elements like a monitored ventilation fan and fail-safe gas shut-off valves prevent hazards, while calorific values up to 50 MJ/m³ support CHP optimization.

Continuous data output via Modbus RTU and 4–20 mA signals enables predictive maintenance, reducing equipment failures and operating costs by streamlining acid gas filtration and flow regulation (40–60 l/h).

Together, the OPTIMAX and SWG100 Biogas Analyzer form a comprehensive toolkit for the biogas industry, bridging portable diagnostics with stationary reliability

As facilities scale toward net-zero goals, these analyzers spot inefficiencies and actively eliminate them, fostering resilient, high-output operations.

For biogas pioneers, investing in such precision is essential for a greener, more profitable future.

To learn more about how the OPTIMAX and SWG100 Biogas Analyzers can enhance your operations, contact us at: MRU-Instruments.com

For more information, read our Efficiency Magazine.

Comments