Modular Solutions Powering the Next Generation of RNG Projects

By Kingsbury Companies LLC

As renewable natural gas (RNG) development accelerates across North America, project developers are under increasing pressure to deliver efficient, cost-effective, and scalable solutions.

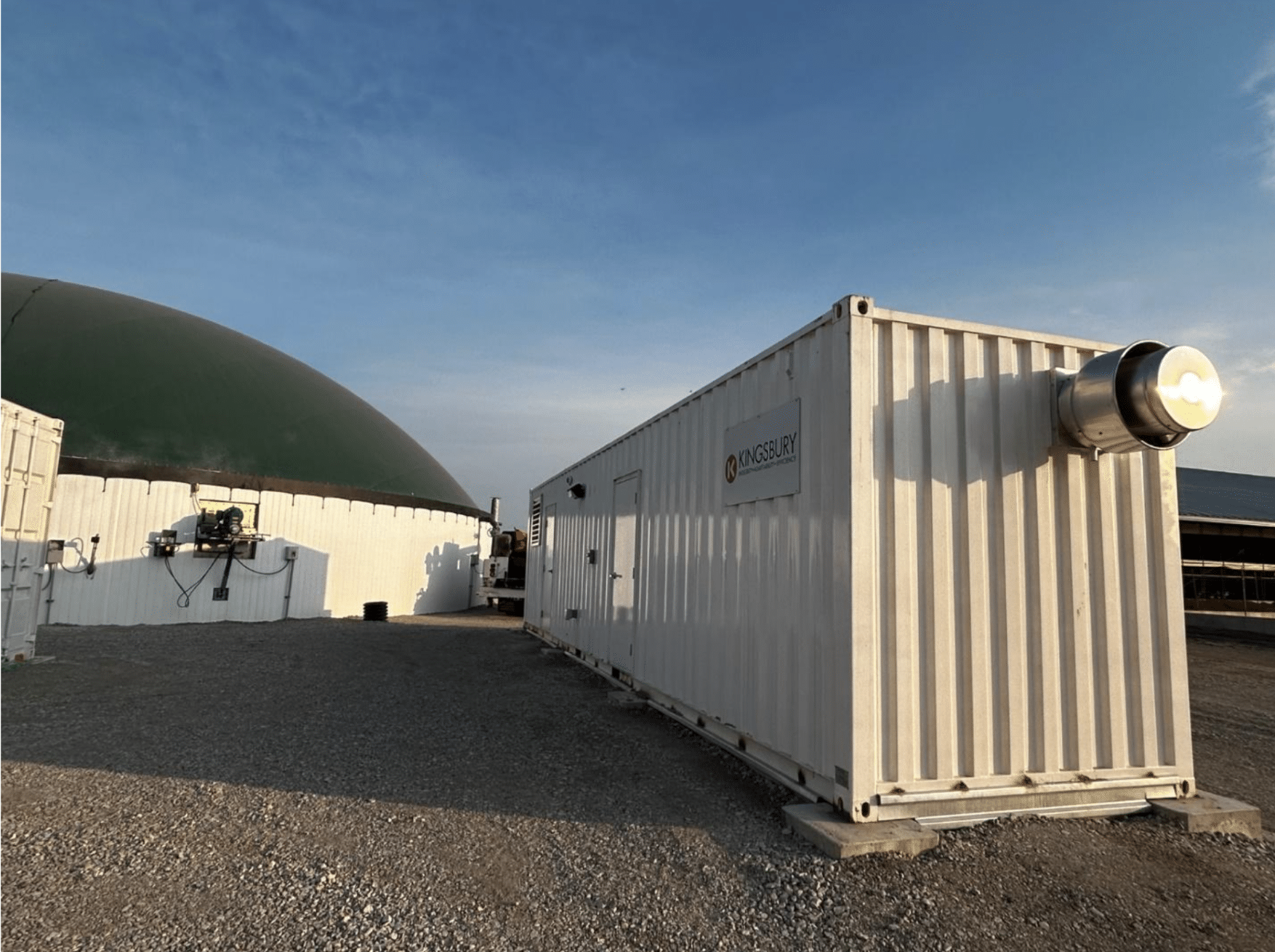

Modular container systems, self-contained units that integrate critical components such as pumps, boilers, heat exchangers, and electrical systems, are redefining how RNG plants are built and operated. Kingsbury Companies, a Vermont-based heavy civil contractor with over four decades of experience, is leading this transformation.

Kingsbury this year has been working on delivering fully equipped modular containers in New Mexico, Wisconsin and Georgia, as well as fully integrating electrical and control container units in Indiana and Ohio, ensuring seamless installation and start-up for the RNG plants’ overall commissioning.

By consolidating essential systems into compact, transportable units, the company helped the biogas industry reduce on-site construction time and costs while maintaining the highest engineering standards.

Each unit was factory-tested, ensuring plug-and-play readiness upon delivery, a critical advantage for remote projects facing labour shortages.

Kingsbury’s modular approach offers significant efficiency gains at every project stage. Pre-engineering and 3D modelling allow contractors and engineers to visualize layouts before fabrication, reducing design revisions and field errors.

This precision enables utility piping and foundations to be prepared in advance, accelerating installation and minimizing costly delays. For developers, that means faster commissioning, predictable budgets, and lower risk exposure.

The economic impact is equally compelling. By shifting complex technical work to controlled environments, modular fabrication minimizes the need for specialized on-site labour, an advantage in rural areas where travel and housing costs can inflate budgets.

Additionally, standardized components improve maintenance efficiency and spare-parts management, giving operators consistent performance across multiple facilities.

From an environmental perspective, modular construction supports the broader decarbonization goals driving the RNG sector. Shorter construction schedules translate to lower emissions from heavy equipment, while factory testing ensures leak-free operation and optimized energy use from day one.

Looking ahead, Kingsbury Companies continues to expand its modular technology across the renewable energy landscape. Kingsbury has done similar work for gas utility companies, biogas developers, technology manufacturers, hydro-electrical facilities, and many others in these industries. With ongoing projects across the USA, the company is helping clients accelerate biogas production timelines and maximize ROI. As new markets emerge for CO₂ recovery, sustainable aviation fuel, and hydrogen, modular construction will remain a cornerstone of efficiency.

By standing by their word, work knowledge and reliability, every time, Kingsbury Companies is not only building infrastructure, but also building the future of clean energy.

For more information, read our Efficiency Magazine.

Comments