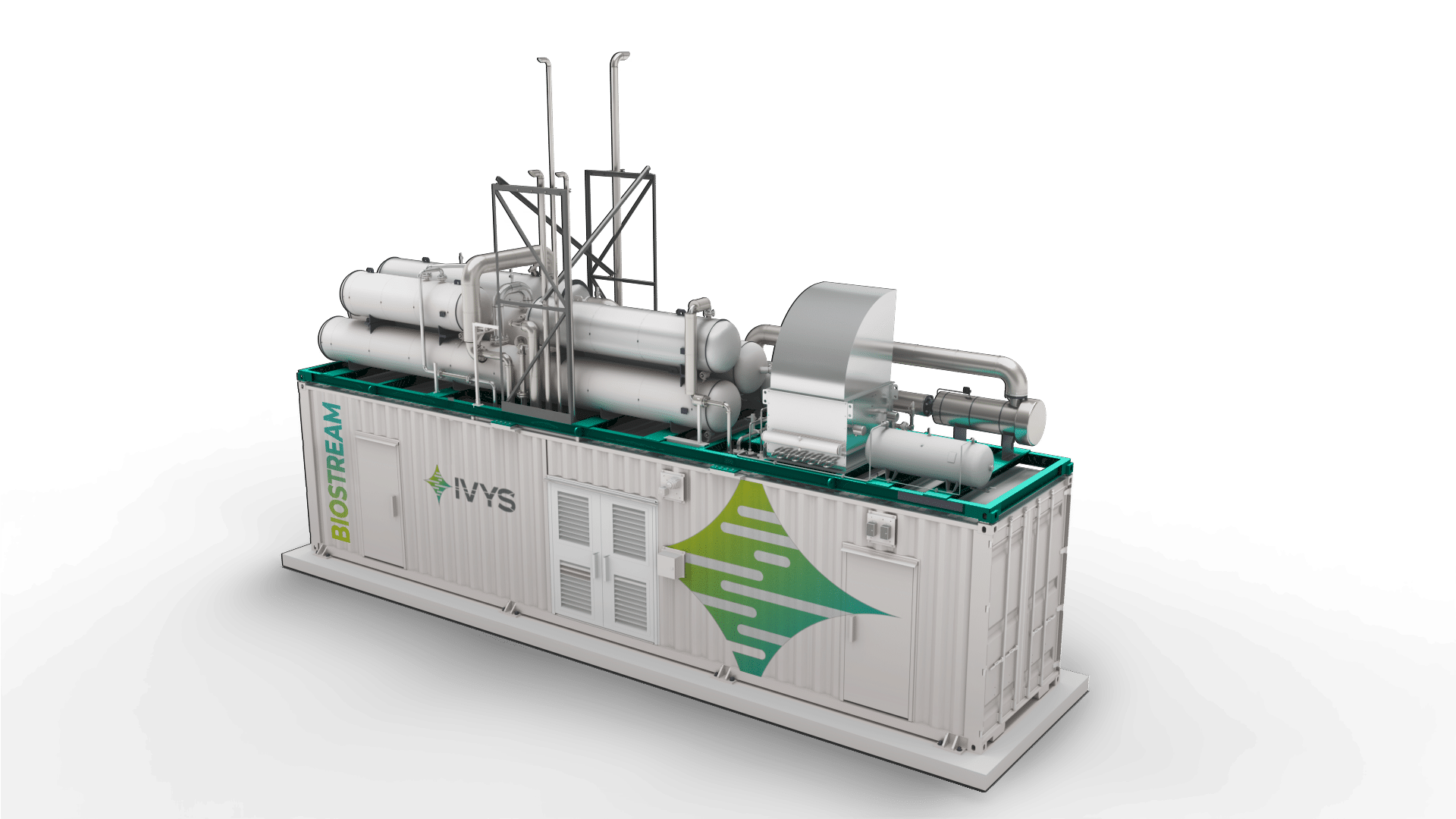

IVYS’S BIOSTREAM – Translating Efficiency into Profitability in Biogas Upgrading

By Ivys Adsorption

Upgrading raw biogas—primarily methane and carbon dioxide—into pipeline-quality renewable natural gas (RNG) presents a critical challenge for producers.

Success hinges on meeting stringent purity standards, maximizing methane recovery, and minimizing operating costs.

Ivys Adsorption’s Biostream system addresses these demands with a high-efficiency, adaptive control platform that continuously optimizes performance across all operating conditions.

Maximizing Methane Recovery

Methane recovery is directly tied to revenue. A mere 1% drop in recovery can translate to nearly $1 million in lost income over a decade for a 900 SCFM raw biogas plant selling RNG at $30/MMBTU.

While most upgrading technologies offer fixed recovery rates under ideal conditions, real-world fluctuations in biogas flow and composition can erode performance.

The Biostream’s advanced control system dynamically adjusts to these variations using over 100 integrated sensors and proprietary algorithms.

Combined with rotary valve technology, the system consistently achieves methane recovery rates exceeding 99%*, minimizing losses and maximizing yield.

Low Operating Cost and High Reliability

Efficiency isn’t just about recovery, it’s also about cost control. Biostream’s adaptive control system delivers exceptional energy performance, consuming just 0.26–0.30 kW/NCMH of raw biogas.

A built-in preventive maintenance control interface alerts operators before issues arise, reducing unplanned downtime and supporting plant availability above 98%*. With adsorbents engineered to last over 10 years, the PSA unit offers long-term durability and minimal maintenance overhead.

Consistent RNG Quality

RNG must meet strict pipeline specifications to be marketable. Biostream ensures methane purity above 97%* while effectively managing trace contaminants. It reliably meets injection standards such as PG&E’s Gas Rule 21, which requires CO₂ levels below 1%, helping producers avoid costly off-spec penalties and maintain steady revenue streams.

Streamlined Deployment and Automation

Biostream’s standardized, containerized design simplifies permitting, inspection, and installation—reducing EPC costs and accelerating time-to-operation.

Its modular architecture supports future expansion or relocation, making it ideal for developers with multi-site portfolios.

Operational complexity is reduced to a three-button interface—START, STOP, TRIP—backed by SCADA automation, remote monitoring, and centralized performance dashboards.

Efficiency That Pays Off

By combining high methane recovery, low energy use, and rapid deployment, Biostream transforms system efficiency into bottom-line profitability.

For biogas producers, it’s not just an upgrade—it’s a smarter way to monetize every molecule.

*Contact Ivys to validate performance metrics under your project’s specific operating conditions.

For more information, read our Efficiency Magazine.

Comments