Over 65,000 Hours of Operation for Ivys’s Biostream

Over 65,000 Hours of Operation for Ivys’s Biostream on Midwest Dairy Farms

By Ivys Adsorption

As of July 31, 2025, twelve Ivys Biostream units operating across six dairy farms in Idaho and Iowa have logged more than 65,000 cumulative operating hours, upgrading raw biogas into renewable natural gas (RNG).

Operations began in fall 2024, and ongoing performance optimization is driven by continuous remote monitoring and active collaboration between Ivys’s engineering team and our customers.

The fleet is currently achieving methane recovery rates exceeding 98.5% and RNG purity greater than 96.5%. Collectively, the six sites have a combined RNG production capacity of 5,400 NCMH (3,360 SCFM).

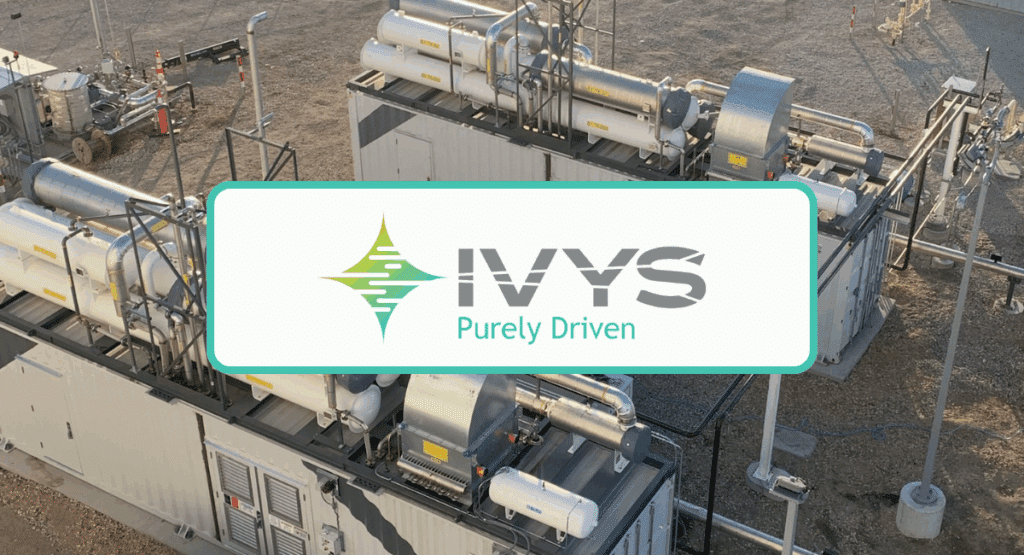

Ivys’s Biostream is a fully containerized biogas upgrading system engineered for reliability, efficiency, and high performance.

At its core is our proprietary pressure swing adsorption (PSA) technology—one of the most compact, economical, and dependable gas purification systems on the market.

The PSA uses fast-cycle rotary valve technology and advanced adsorbents to remove contaminants such as VOCs, enabling maximum methane recovery even with fluctuating feed conditions.

Key specifications of Biostream include:

• Methane purity: >97%

• Methane recovery: Up to 99%

• Adsorbent lifespan: 10+ years (within inlet flow specifications)

• Proven track record: Over 100 installations worldwide in dairy, agricultural waste, wastewater, and other biomass applications

“We’re excited about our partnership with the biogas facility developer at these Midwest dairy farms,” said Cristian Iuhas, Vice President of Innovation at Ivys Adsorption.

“This collaboration allows farmers to generate new revenue from manure, significantly reduce greenhouse gas emissions, and strengthen local energy security. Ivys’s twelve Biostreams will deliver efficient, reliable RNG production for years to come.”

Now that all units are fully operational, Ivys’s engineers offer support through remote monitoring.

Each Biostream is equipped with over 150 sensors, continuously tracking metrics such as inlet and product flow rates, methane recovery, RNG purity, CO₂ output, and uptime.

This data is automatically compiled into Key Performance Indicator (KPI) reports, enabling facility comparisons, trend analysis, and targeted process improvements.

Remote monitoring also streamlines predictive maintenance, with automated tracking of all usage- or time-based service requirements, ensuring the Biostream fleet operates at peak performance.

For more information, read our USA Biogas Magazine.

Comments