Transforming Organic Waste into Sustainable Energy

By Adekom

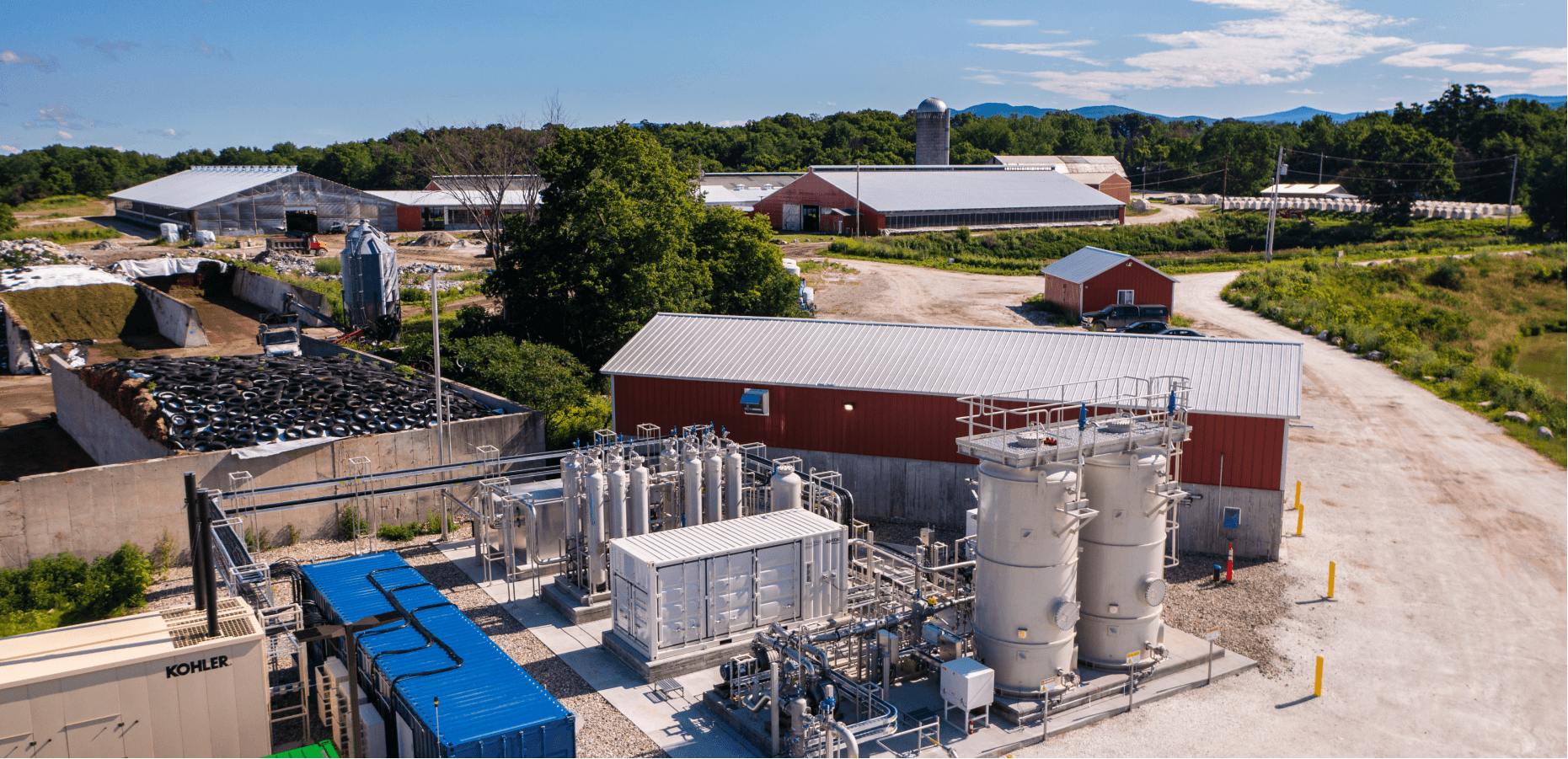

In June 2021, the Goodrich Family Farm in Salisbury, Vermont, inaugurated a significant renewable energy project: an anaerobic digester facility designed to convert organic waste into renewable natural gas (RNG).

This facility processes approximately 180 tons of food and beverage waste daily, sourced from manufacturers, retailers, and distributors, alongside 100 tons of dairy manure from the farm’s 900-cow herd.

The biogas produced is upgraded to RNG and injected into the Vermont Gas (VGS) pipeline system.

Key Features of the Facility

Anaerobic Digestion Process

The facility employs anaerobic digestion to break down organic materials in an oxygen-free environment, producing biogas primarily composed of methane. This process not only generates renewable energy but also reduces greenhouse gas emissions from organic waste.

RNG Production and Distribution

The upgraded RNG is injected into the VGS pipeline, making it available for various consumers, including Middlebury College, which has committed to purchasing about 55% of the RNG produced annually. This is expected to supply approximately one-third of the college’s heating and cooling energy needs.

Environmental Benefits

The project contributes to improved air and water quality by reducing methane emissions from manure and food waste.

Additionally, the phosphorus removal system extracts potentially harmful nutrients from the digestate before it is converted into fertilizer and applied to farmland, thereby protecting local water bodies like Lake Champlain.

Community and Educational Impact

The facility serves as a model for sustainable agriculture and renewable energy, offering opportunities for research, student projects, and educational enrichment. It also provides local employment and supports the regional economy by processing organic waste into valuable energy.

ADEKOM has:

– Provided a 250 kW Variable Speed Drive (VSD) Containerized Biogas Screw Compressor package operating at 13.8 bar for gas conditioning and compression

– Installed upstream of a Pressure Swing Adsorption (PSA) upgrading unit in this project.

The complete compressor package, including vessels, heat exchangers, and pipework, was designed following ASME standards, and the electrical components comply with UL standard Class 1, Division 2, Group D.

Since commissioning in June 2021, the system has been processing over 30,000 Nm³ of raw biogas daily, upgrading it to Renewable Natural Gas (RNG).

This project exemplifies a successful collaboration between a dairy farm, renewable energy developers, a natural gas utility, and an educational institution, highlighting the potential for integrated solutions in sustainable energy and waste management.

For more information, read our Canadian Biogas Magazine.

Comments