Hydron Energy’s INTRUPTor Solution for Biogas Upgrading

Hydron Energy’s INTRUPTor Solution for Biogas Upgrading: The INTRUPTor

By Hydron Energy

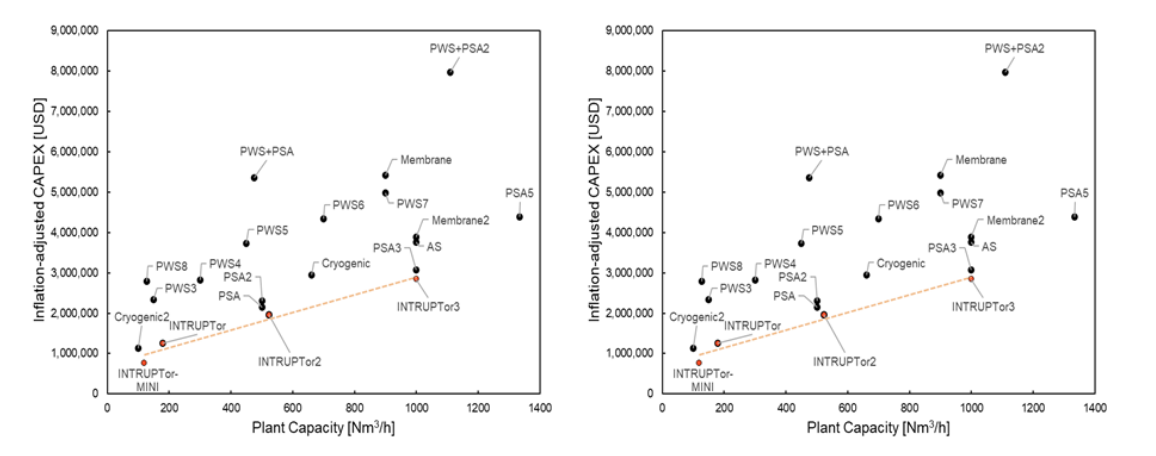

One of the main barriers seen in the development of the Biogas Upgrading market is RNG projects can require high capital costs for construction and equipment. High production costs hinder the growth of the RNG industry and securing financing can be difficult due to hesitancy among lenders to these projects. While our governments have set RNG targets as part of their net-zero goals, the reality is that we are far behind in meeting these targets. Hydron Energy, founded in 2020 in Vancouver, BC, has developed a revolutionary novel gas separation system by mimicking the natural process. Nature uses mild process conditions, near-ambient pressures and temperatures, and relies on flexible coordination chemistry. We investigated natural gas eparation processes and implemented what we learned to develop a low-cost biogas upgrading solution; the INTRUPTor.

The INTRUPTor system is currently operating in Ontario, Canada, and the results are as we predicted (best performance):

- Purity: 99.9%.

- Recovery: 99.95%.

- Productivity: Biogas processed/footprint 20/hr.

Efficiency and Low Cost

Operating near ambient conditions, as nature does, led to our novel low-pressure and low-energy system, which reduces capital and operating costs by an average of 50% compared to conventional upgrading products and delivers an industry-leading carbon intensity score.

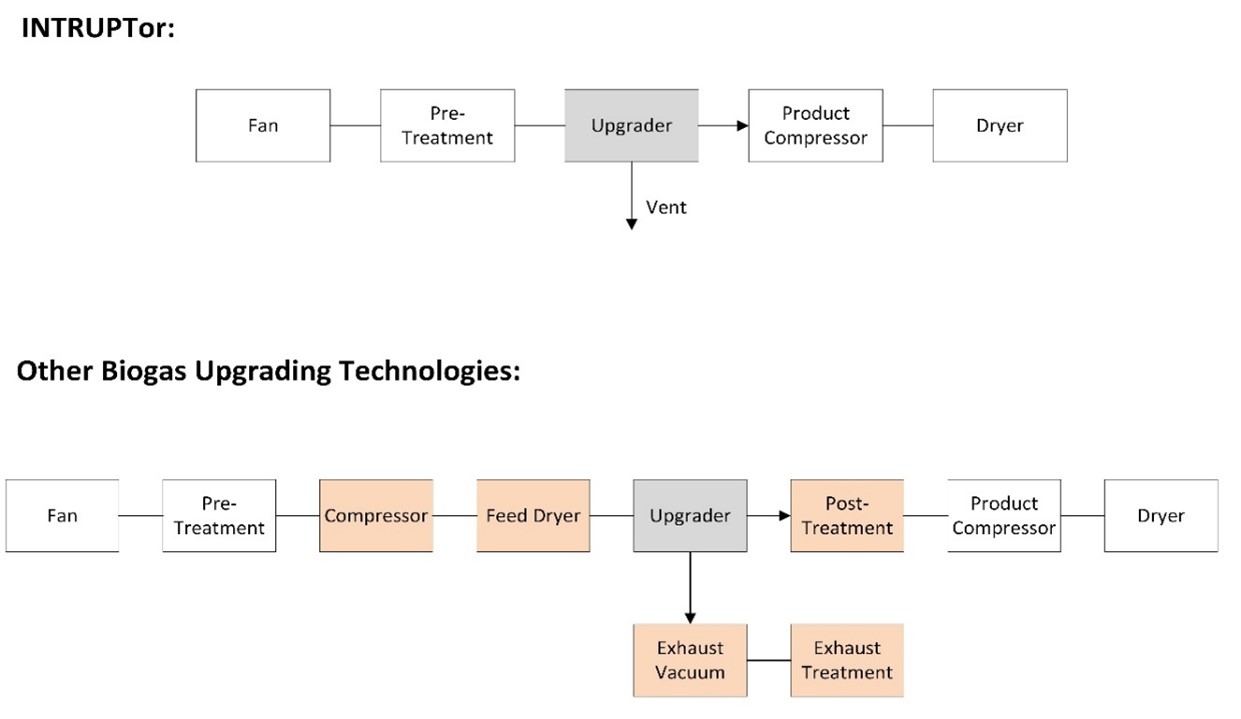

How the INTERUPTor Lowers Capital and Operating Costs

- Compressor: No feed compressor is required.

- Pre-treatment: No dryer is required prior to upgrading unit operation.

- Post-treatment: Due to significant high recovery, no need for exhaust post-treatment for methane slippage recovery.

Commercializing the INTRUPT

The INTRUPTor – Mobile (40 – 220 Nm3/hr ) and our stationary INTRUPTor units Mini (40 – 220 Nm3/hr ), Mid (240– 1200 Nm3/hr ), and Max (1250 – 3800 Nm3/hr) are on sale now.

The INTRUPTor – Mobile will unlock access to RNG production for dispersed feedstocks and produce RNG onsite for local fueling needs or to a virtual pipeline system.

For more information about Hydron Energy and the INTERUPTor Units, visit our website at https://hydron.ca, or contact us via email at info@hydron.ca.

For more information, read our Biogas Italian Magazine.

Comments