Does H₂S Removal Equipment Compromise Your Biogas Facility?

Is Your H₂S Removal Equipment Compromising Your Biogas Facility’s Bottom Line?

By Brad Douville, CEO, Greenlane Renewables

Hydrogen sulfide (H2S) is a highly toxic and corrosive gas present in every biofuel project. It must be removed before biogas can be used as a renewable fuel. H2S can not only affect the health and safety of facility workers and impact the environment, but it can also damage downstream equipment.

The High Cost of Not Selecting the Right H₂S Removal Technology

Not selecting the right H2S removal technology can significantly impact a biogas facility’s bottom line. Inefficient systems may lead to lost revenue due to downtime and being shut out of the pipeline. It can also lead to increased operational costs. Passive media systems, while simple, can require frequent media replacement. This not only can result in high operational costs but can lead to production interruptions. Biological scrubbing systems can be complex and sensitive to changes in biogas composition, making them prone to potential failures.

Certain typical methods of H2S removal, including passive activated carbon media and biological scrubbing, can be limited in their effectiveness and expensive to maintain, especially due to their need for oxygen, which is not normally present in biogas generated from anaerobic digesters. Greenlane’s Cascade H2S offers a highly efficient solution for H2S removal from biogas from anaerobic digesters and requires no oxygen to be added. Oxygen is very difficult for downstream biogas upgrading equipment to remove. Therefore, by adding it for other H2S removal methods puts at risk the ability to consistently and reliably meet renewable natural gas (“RNG”) pipeline injection specifications.

Greenlane’s Cascade H₂S System

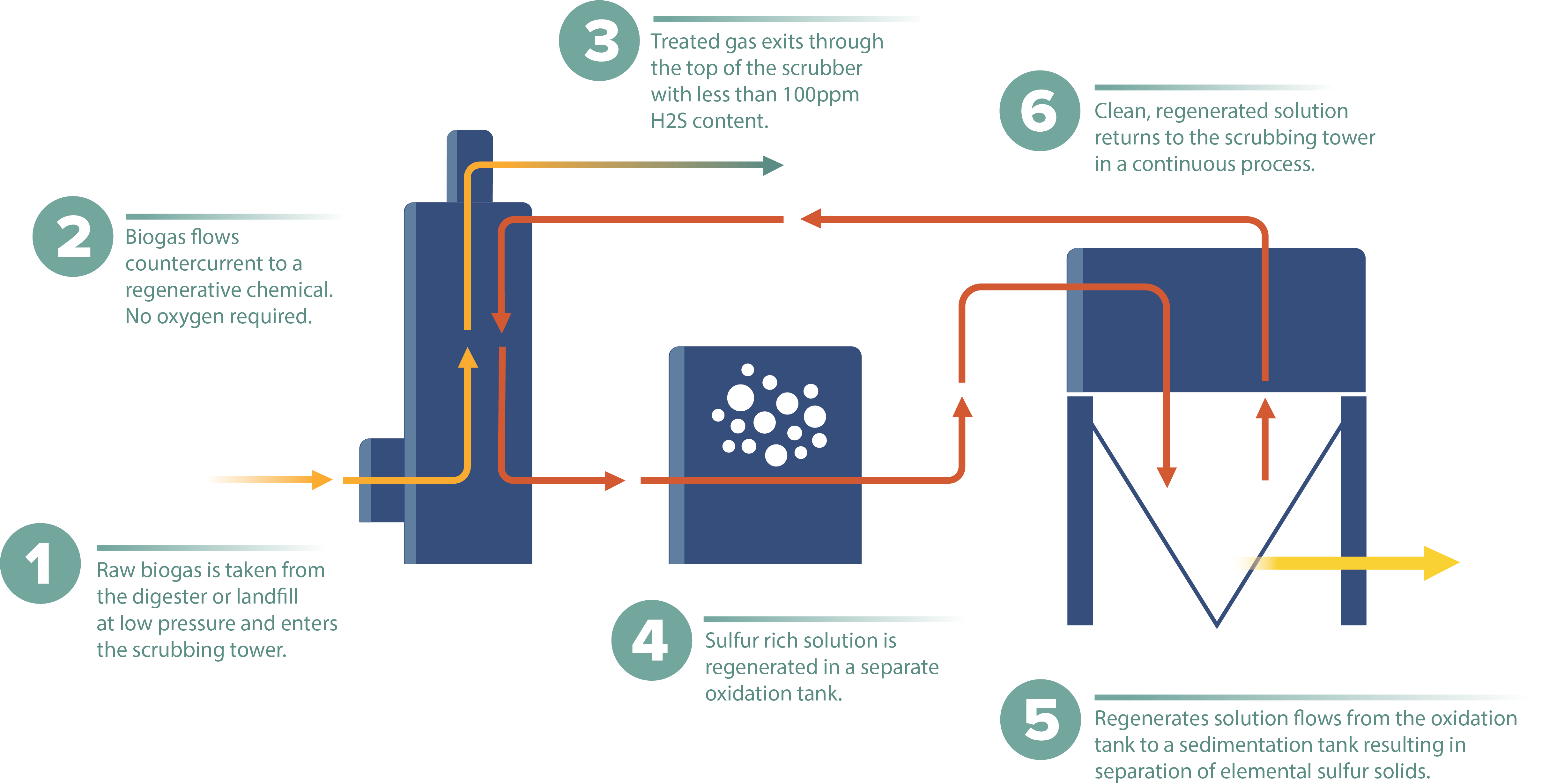

Greenlane’s Cascade H2S system offers a more efficient and economical solution for H2S removal in biogas generated in anaerobic digesters. It employs a two-step process of bulk reduction and polishing to remove H2S effectively. The diagram below illustrates the basic process of the Cascade H2S, excluding the polishing step.

The Cascade H2S offers a scalable design and simple plug-and-play installation, making it suitable for a wide range of biogas facilities. Skipping complex setup processes and eliminating the time for biological processes to mature allows for a faster path to operation. By adopting Cascade H2S, operators can optimize their biogas production processes, minimize downtime, and improve overall profitability. This technology captures large quantities of pollutants and does not return a by-product to be disposed of, but instead returns a fertilizer that provides an ecological and sustainable solution.

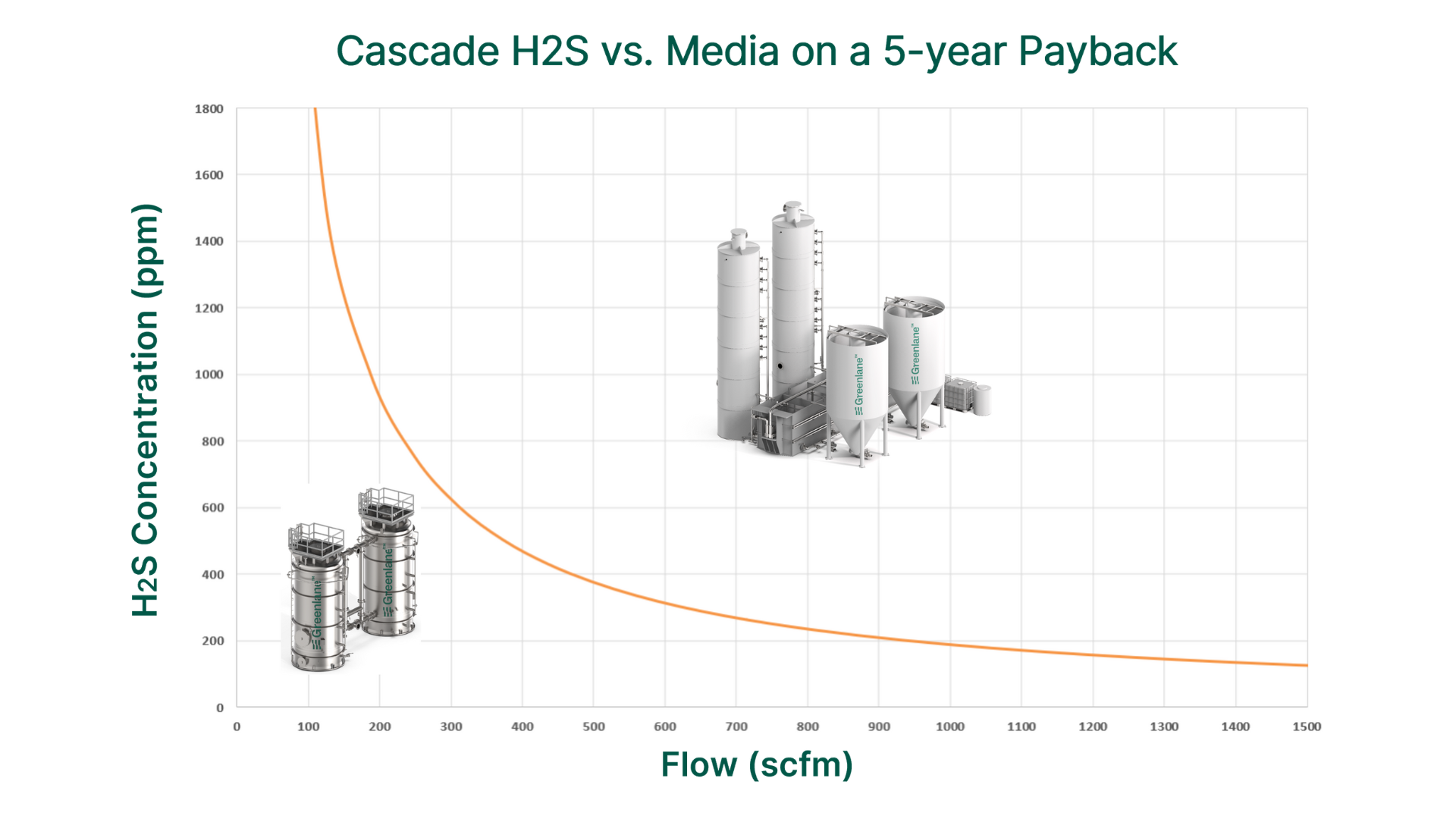

This graph illustrates the cost savings potential of a Cascade H2S system compared to a passive media-only system. Facilities operating on the high side of the curve would quickly see significant cost savings.

Biogas facilities must remove H2S to ensure safety, environmental compliance, and economic viability. With over 160 installations worldwide, including eight deployed in North America over the last two years, Greenlane’s Cascade H2S has a proven track record of delivering reliable and efficient H2S removal. Its efficiency, cost-effectiveness, scalability, and ease of installation make it an excellent choice for biogas facilities looking to enhance their operations.

For more information, read our Biogas Efficiency Magazine.

Comments