How to Minimize Natural Gas Compressor Costs & Safety Risks

Written by Ingersoll Rand

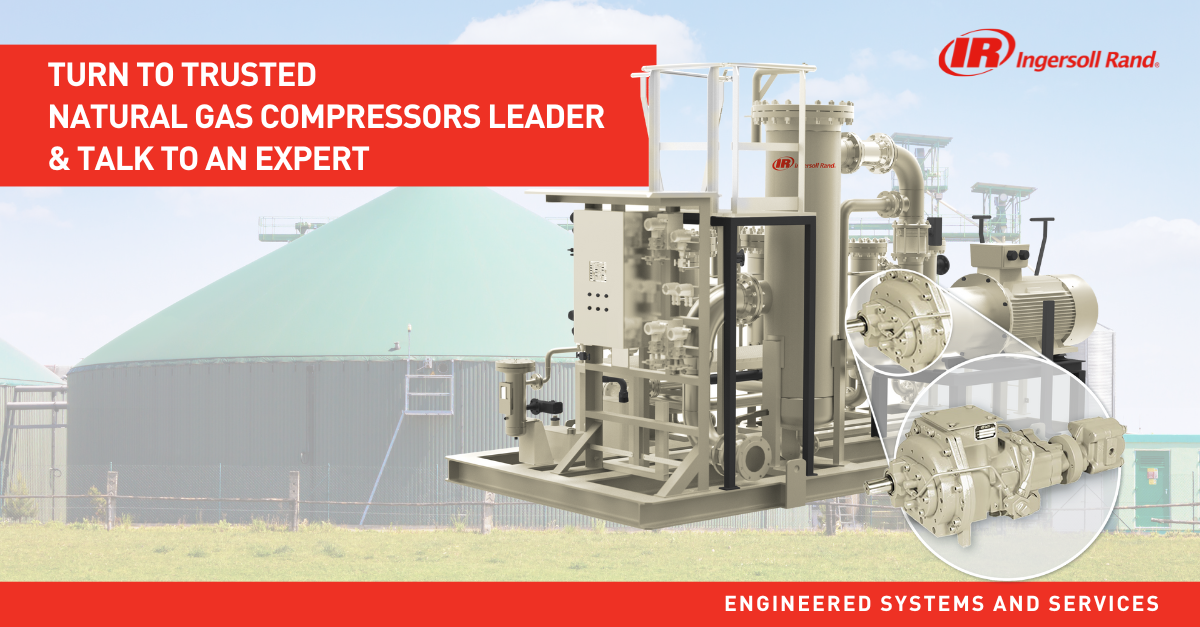

In the biogas industry, ensuring reliability, safety, and efficiency is of utmost importance. Ingersoll Rand boasts extensive expertise in delivering gas ends and complete natural gas compressor packages tailored to the unique technical specifications of our customers within the biogas sector. These packages are meticulously engineered to fulfil the demanding safety needs of biogas compression, as well as various other gas-related applications.

Tips for Minimizing Compressors Costs While Ensuring Safety

Only by understanding the importance of choosing the right compressor technology and configuration can you hope to successfully minimise costs in Renewable Natural Gas (RNG) plants. The following tips can help you better manage costs and maximize safety:

Minimize the Areas Where Equipment has to be Modified

Modification of equipment to meet the requirements of classified areas can multiply the cost of that equipment; additionally, not all equipment can be modified in a way that meets those requirements. As a result, wherever possible confine that need to modify equipment to as small an area as possible.

Move the Compressors

If there is a chance to move the gas compressors, do it. Sometimes, simply moving the proposed compressor installation a short distance into a better-ventilated area can help you reduce costs. The cost of piping will almost always be less than the modifications required to install the compressor in a classified zone. Having the compressed gas system in an unclassified area can help to improve the safety of the entire biogas or biomethane plant.

Compressor Design

The best prevention is to address hazards at the design stage of machinery and plant.

Compressor Training

Users must be trained on the relevant equipment and should not work alone. Ensure only trained personnel operate any compressed gas equipment.

Other important tips:

- Ensure that the moving parts of the compressor are correctly guarded.

- Undertake risk assessments in hazardous areas.

- Ensure that pressure-release valves and air vents are free from obstruction.

- Ensure machine monitoring systems are provided.

- Make sure that safety protection measures such as gas and flame detectors are implemented depending on area class.

To learn more, read our Safety Magazine.

Comments