The Role of Monitoring and AI in Biogas Plant Safety

Written by Farid Sayedin, PhD, PEng, Senior Process Manager at Anessa.

Safety in a biogas plant is crucial to protect both personnel working in the facility and the surrounding environment. Effective monitoring systems in biogas plants contribute significantly to maintaining a safe working environment, protecting personnel, preventing environmental incidents, and ensuring the efficient and sustainable operation of the plant. In this article, several aspects of safety and the role of monitoring are outlined.

- CH4 and H2S Detection: Continuous monitoring of gas levels, including methane (CH₄), carbon dioxide (CO₂), and hydrogen sulfide (H₂S), is The accumulation of methane beyond safe limits in some process areas can cause explosions. Moreover, exposure to hydrogen sulfide, even at concentrations as low as a few hundred ppm, can cause severe damage. The presence of early detection monitoring systems and emergency response plans enables prompt action to prevent hazards such as explosions or exposure to toxic gases and minimize the associated risks.

- Temperature and Pressure: Abnormal temperature or pressure fluctuations can indicate potential equipment malfunction or hazards such as leaks or blockage. These parameters in biogas plants can be easily monitored to make sure they are within safe limits.

- Oxygen Levels: Around 40% of biogas is CO2, which can be separated and sold as a product in biogas plants. Even though CO2 is non-flammable and non-toxic, it is a colorless, odorless gas that can displace oxygen in confined spaces, leading to asphyxiation. Monitoring oxygen (O₂) levels in confined areas where personnel can enter is important to minimize the risk.

- Fire Detection: Fire detection systems, such as smoke detectors and heat sensors, are important in biogas plants to immediately detect and alert personnel to potential fire hazards, especially in areas where biogas is present.

- Environmental Monitoring: Monitoring of environmental parameters such as air quality and water quality (e.g., effluent of different units) is necessary to ensure compliance with regulatory requirements and protect the environment from contamination.

- Control Systems: Integrating monitoring systems with control systems enables automated responses to alarms or abnormal conditions, such as activating ventilation systems, shutting down equipment, or triggering emergencies. In situations like gas leaks and the presence of H₂S, the severity of damage is directly proportional to the duration of exposure. Therefore, quicker response measures significantly reduce the risk.

Monitoring can take advantage of artificial intelligence (AI) to enhance the safety of biogas plants by utilizing advanced data analytics, predictive modeling, and automation capabilities. For example, AI algorithms can analyze data from sensors monitoring equipment such as pumps, valves, and digesters to detect anomalies or early signs of equipment malfunctions. Early detection helps prevent potential hazards such as leaks, overpressurization, or breakdowns that could lead to safety incidents.

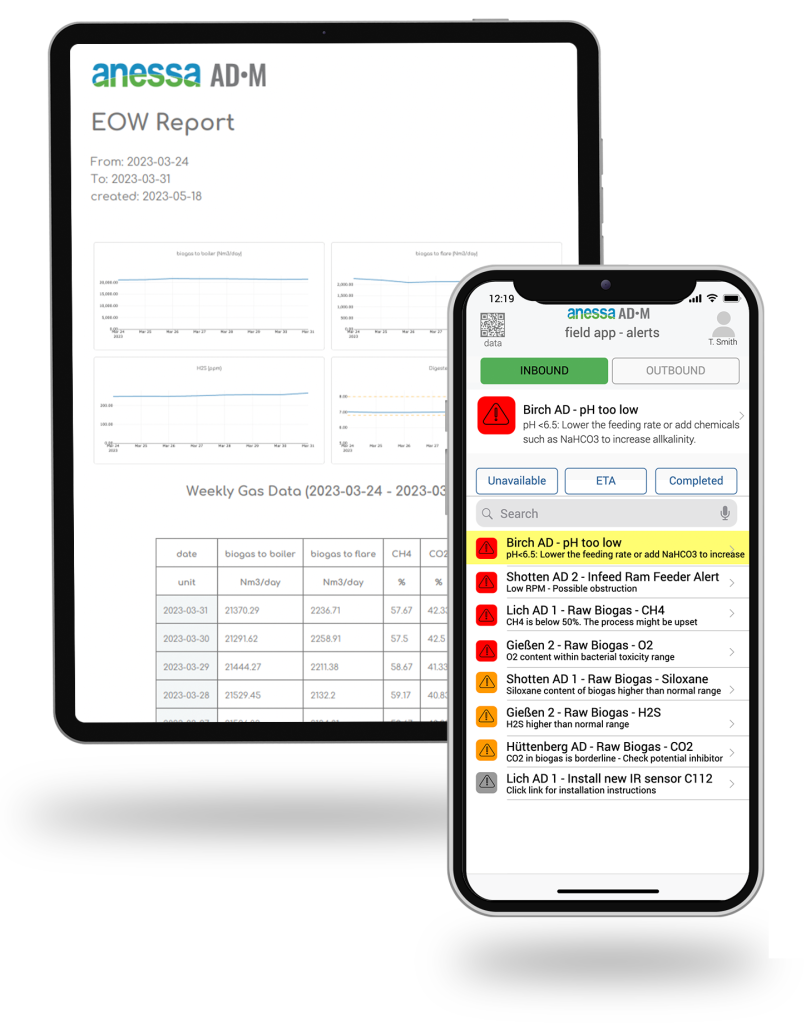

The Anessa monitoring platform automatically collects data from various plant sensors, visualizes system trends and behaviors, and alerts operators to out-of-range values or hazardous situations. Additionally, the platform can integrate the plant’s response plan and standard operating procedures (SOP) to ensure appropriate actions are taken.

To learn more, read our Safety Magazine.

Comments