Maximizing Efficiency and Versatility: Boerger Bioselect Screw Press Separator

Biogas production relies on the process of anaerobic digestion, where microorganisms break down organic materials to produce biogas. Digestate, the remaining nutrient-rich byproduct of the biogas plant, is frequently separated into solid and liquid fractions using liquid/solid separators such as screw press separators. Solid/liquid separation turns the digestate waste into two usable products; the liquid fraction, commonly utilized as fertilizer and for irrigation, and the digestate solids, suitable for applications like cattle bedding, providing valuable resources from the separation process.

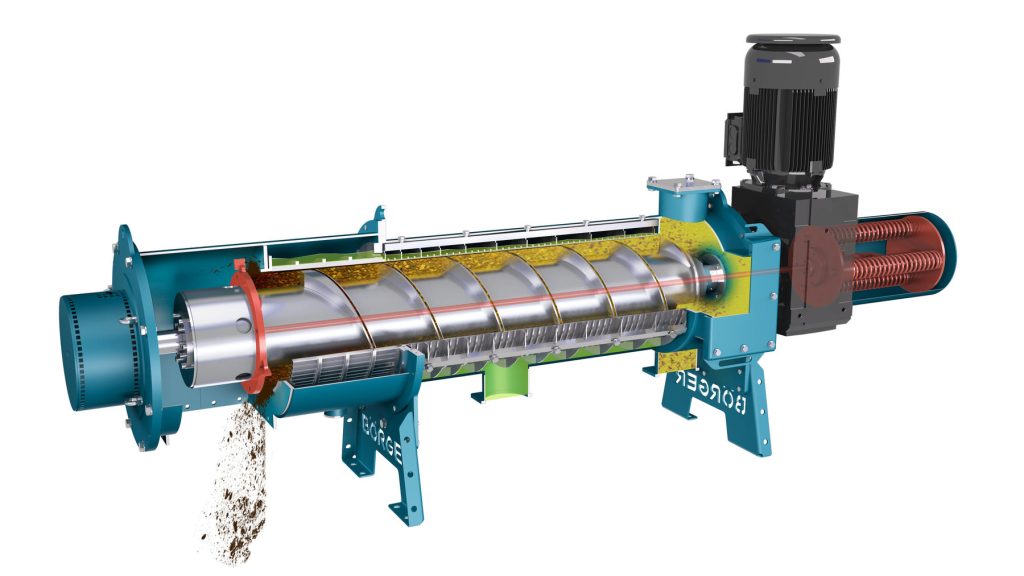

The Boerger Bioselect screw press separator features two energy-efficient designs, the Bioselect BS for manure thickening and the Bioselect RC for full separation, with multiple sizes, to fit the various needs of customers. The RC150 is the largest screw press one on the market, with a maximum capacity of 150 m3/h (660 gpm) capable of drying the solids to a solid content of 38%.

The Boerger Bioselect offers a turnkey solution, combining the separator, pump(s), and control unit into a single, ready-to-connect unit. The control unit optimally coordinates the operation of the pump and separator, maximizing the Bioselect’s capacity utilization.

Unlike typical screw press separators, the Boerger Bioselect features a patented profile auger with a counter bearing, keeping the screens clean and eliminating rubbing wear between the auger and filter for exceptional service life.

A standout feature of the Bioselect is its closed-loop system. The rotating Multi Disc design ensures leakproof operation, with the slurry never exposed to atmospheric air until discharge. This non-vented, positive-pressure system prevents entry of oxygen to the liquid throughout the process.

Maintenance of the Bioselect is straightforward, with the auger easily removable from the drive shaft through a maintenance opening. This enables on-site maintenance without the need for extensive piping or drive system removal, allowing operators to perform maintenance tasks quickly and efficiently themselves.

The Bioselect offers versatility in installation options, accommodating various spatial and operational needs. Whether mounted on a bracket, integrated with a movable frame and macerator, or configured for mobile use, the Bioselect effortlessly adapts to diverse applications. Boerger’s commitment to customization extends to discharge height, pump selection, and control technology, ensuring optimal performance in any environment. Additionally, multiple separators can be installed side by side, including mobile versions, to handle high separation quantities efficiently.

Boerger’s commitment to innovation ensures that the Bioselect remains at the forefront of solid-liquid separation technology. Its ease of maintenance and customizable installation options make it a preferred choice for Biogas plants seeking optimal efficiency and reliability.

For more information and biogas projects, read BiogasWorld’s US Biogas Magazine.

Comments